When it comes to egg tray machines, there are three basic types: manual. semi-automatic and automatic. It is important to understand the difference between manual and automatic so that you can decide which one is the best choice for your business. There are advantages and disadvantages to both. When choosing which one to buy, it is important to consider the needs of your business so that you can select a suitable egg tray machine that will help you meet your production goals.

Manual egg carton making machine is ideal for businesses that have relatively low production needs or that don’t have a lot of money to invest. If you are looking to get started in the egg tray making business but don’t have a ton of startup capital, investing in one of these machines is a great option. They are generally more affordable than automatic egg tray machines. At the same time, however, they will allow you to get your business up and running for a relatively small investment.

One of the primary differences between manual and fully automatic egg tray making machines is in how the trays are dried. With manual machines, the trays usually have to be removed by hand and either placed in a separate drying machine or dried in the sun. With automatic machines, on the other hand, the drying process is automated, meaning that the trays emerge from the machine fully dried.

Automatic egg tray machines are more expensive than manual machines. However, they also have much higher production capacity. Additionally, they generally require fewer workers in order to operate them, helping to cut down on labor costs.

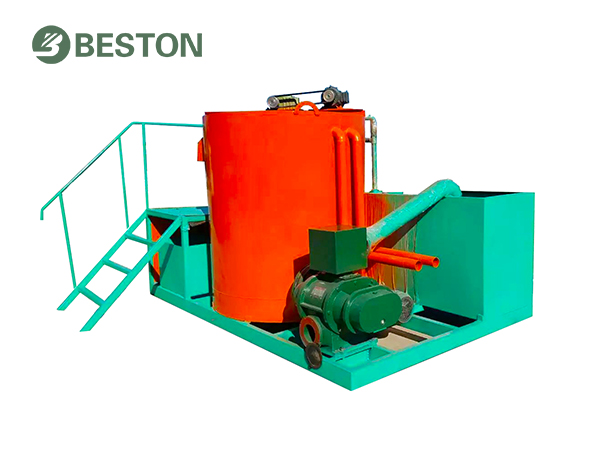

Automatic machines usually consist of several different parts. The first part of the machine that is used is called the pulper. As you might guess, this part of the machine is responsible for turning paper into pulp. Recycled paper is added to the pulper where it is submerged in water and beaten until the fibres of the paper have separated into pulp. Beston Machinery is a professional egg tray machine manufacturer in China, which also provides an integrated pulping system, which can make the small egg tray machines compact, automatic, and efficient.

The pulp is then transferred to the forming system where it is formed over a series of molds. Paper pulp moulding machine is the key section of an egg tray production line. Once the proper shape has been achieved, the finished trays are transferred to the dryer.

The dryers on these machines can vary in terms of their design. Some are designed to dry the trays in a single layer while others can dry multiple layers of trays at the same time. Typically, the dryers are powered either by natural gas or by diesel, depending on the design of the machine. A good egg tray machine supplier will try to save your energy to lower your egg tray machine cost.

Now that you have a better idea of how manual and automatic egg tray machines operate, you should be able to decide which option is right for your business. If you have relatively low production needs and a limited budget, a manual machine is probably the best choice. On the other hand, if you have a little bit more money to spend, going with an automatic machine will help you produce a much larger volume of egg trays with less labor, making it a smart investment for your business. If you cannot make a decision, you can contact Beston pre-sales service for a suitable egg tray manufacturing business plan.